Against the backdrop of advancing the 'Dual Circulation' strategy and 'Made in China 2025,' LE Robotics has successfully developed 'perceptive, cognitive, and actionable' embodied intelligent welding & cutting robots. These robots empower industrial operations in extreme environments and high-end manufacturing. Addressing the limitations of traditional robots with preset programs and insufficient flexibility in complex environments, LE Robotics has achieved breakthroughs in three core capabilities through its 'hardware perception + software decision-making' technology:

Environmental Adaptability

Equipped with a 3D vision multimodal perception system, the robots real-time capture extreme environmental parameters (such as high-altitude low temperatures, intense UV radiation, and dust) and workpiece characteristics. They automatically adapt and dynamically adjust operational postures and process parameters, significantly enhancing equipment stability under complex working conditions.

Edge Decision-Making Capability

Leveraging LE AI, the robots can complete local data processing, path planning, and error correction without cloud support. They maintain continuous operation in network-free or high-interference scenarios, fundamentally overcoming the constraints of 'program rigidity.'

Precision Execution

Through the coordination of high-rigidity mechanical arms and high-precision servo drive systems, the robots translate perceived decisions into millimeter-level precision motion outputs, fundamentally resolving the 'operational deviation' challenges of traditional equipment.

Hu Haojie

CEO of LE Robotics

I have always firmly believed that the value of technology lies in creating perceivable changes for frontline production. Aiming at the disconnection between technology and scenarios caused by the "program rigidity" of traditional robots, LE Robotics has deeply engaged in the industry for years, injecting three core capabilities—environmental adaptability, edge decision-making ability, and precision execution—into embodied intelligence. We reject "parameter games" and are committed to enabling robots to possess the capabilities of industrial workers, including "environmental perception, autonomous decision-making, and precise operation." Every breakthrough originates from in-depth insights into industry pain points.

At Tibet's largest metal structure manufacturing base, LE's embodied intelligent welding robots have been introduced to build an all-chain intelligent solution for the plateau's special environment of "low temperature, low air pressure, and strong light.":

Thermal management design and strong UV-resistant 3D vision cameras are adopted to ensure stable operation of the equipment under extreme temperature differences and strong light, improving weld positioning accuracy.

It supports 7×24-hour continuous operation, improves the welding efficiency of large components through autonomous path planning, and a single device can cover multi-station collaboration, significantly shortening the steel structure manufacturing cycle.

Generate digital archives containing welding parameters to achieve full-process traceability of quality issues. The multi-device cluster management system ensures unified process standards, helping to achieve "zero-defect" quality control.

At a large state-owned petrochemical equipment manufacturing subsidiary, the AI-powered mobile cutting robot "Little Tank" has achieved a full-process upgrade of hole-opening operations through "mobile intelligence + precise execution" for scenarios such as pressure vessels and pipeline prefabrication:

The 3D vision recognition system completes modeling of non-standard workpieces within 5 minutes. LE AI path planning algorithms automatically avoid interference and generate optimal cutting trajectories, replacing traditional cumbersome teaching processes.

High-precision servo drives and robotic arm compensation technology enable sub-millimeter-level cutting control. A standardized process parameter library automatically matches cutting solutions for different materials, eliminating 95% of grinding time in post-processing procedures.

Wireless remote control and a graphical programming interface lower the operation threshold. Ordinary workers can master complex cutting programming through 3D virtual simulation, alleviating the skills gap in high-end equipment manufacturing.

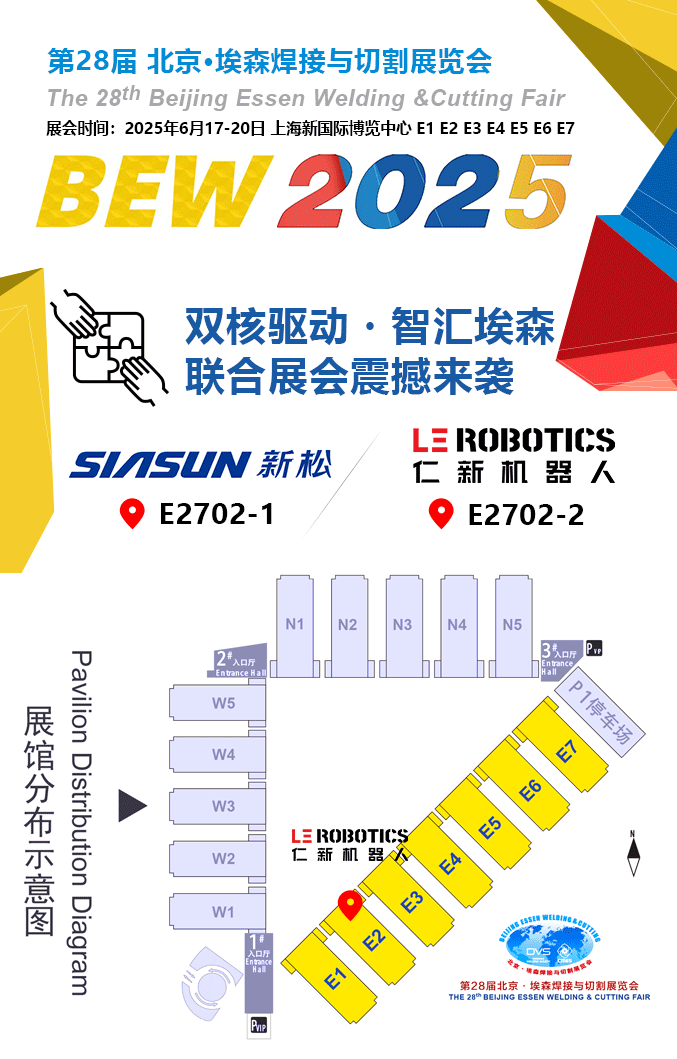

In the wave of industrial intelligence, embodied intelligence has become a key to technological upgrading. In June this year, LE Robotics and Siasun Robot will jointly appear at the Beijing Essen Exhibition (boothsE2702) to showcase innovative achievements and future plans in the field of embodied intelligent welding and cutting.

Since reaching a strategic cooperation in 2024, Siasun has provided hardware with its advantages in robot ontology R&D, while LE Robotics has endowed robots with intelligent decision-making capabilities through advanced algorithms. The jointly developed embodied intelligent welding & cutting robots have been applied at scale in industries such as energy machinery, petrochemical equipment, environmental protection equipment, large-scale heavy industry, and high-end equipment manufacturing. These robots can autonomously plan paths without manual teaching, increasing operational efficiency by over 300%.

Guided by the philosophy of "defining technology through scenarios", LE Robotics is focusing on more national strategic sectors, such as steel structures, shipbuilding, and power construction, deeply embedding embodied intelligence into application scenarios. Through a lightweight solution of "hardware modules + software components", it accurately matches the needs of different industries, driving the global industry toward a more efficient, safe, and green production model.

In the future, the two parties will deepen cooperation in new energy equipment manufacturing and other fields, optimizing algorithms and developing special robots for different needs. Meanwhile, LE Robotics will join hands with multiple AI enterprises to build an open ecosystem, promoting the upgrading of embodied intelligence toward multimodal perception, edge decision-making, and precise control, and helping small and medium-sized enterprises (SMEs) achieve low-cost intelligent transformation. As an innovative practitioner of China's intelligent manufacturing, LE Robotics will continue to lead technological innovation and jointly create a global benchmark for 'Intelligent Manufacturing in China' with ecological partners.** **On June 17, at booths E2701 and E2702 of the Shanghai New International Expo Center, we invite you to witness the breakthroughs and transformations of LE Robotics and Siasun in the field of embodied intelligent welding and cutting!

Contact