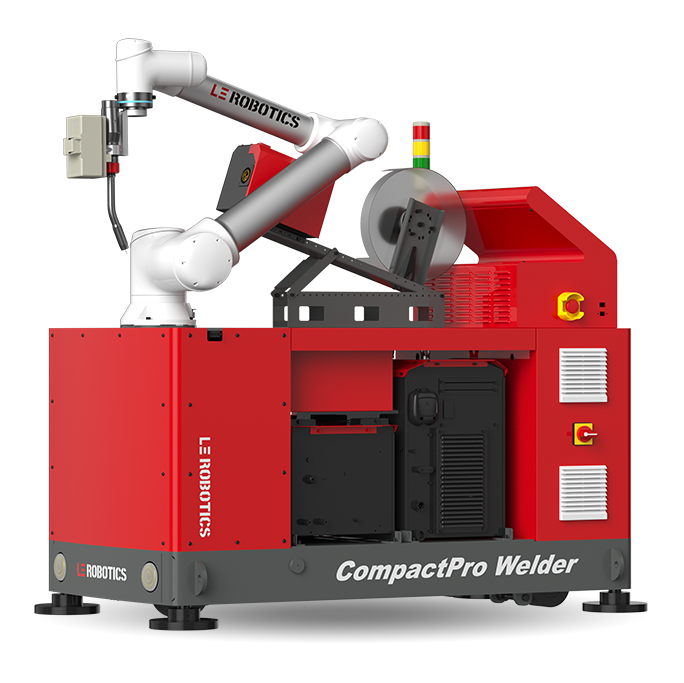

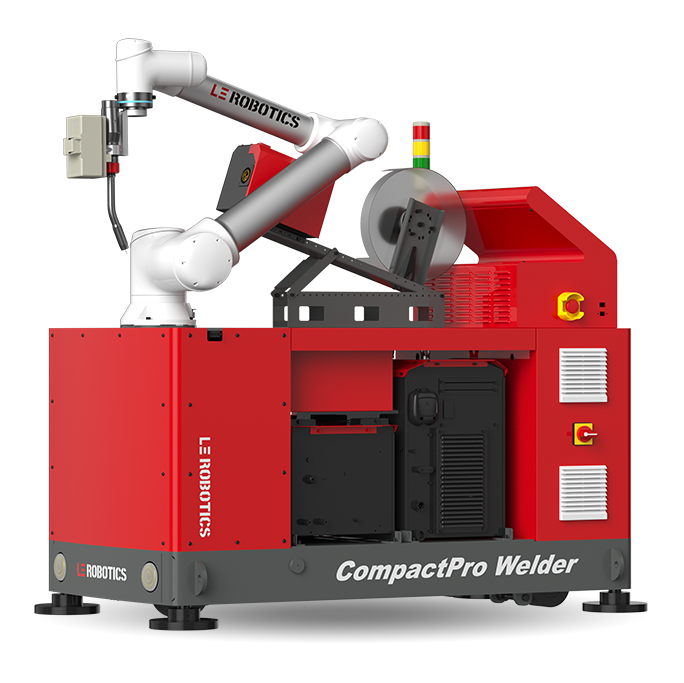

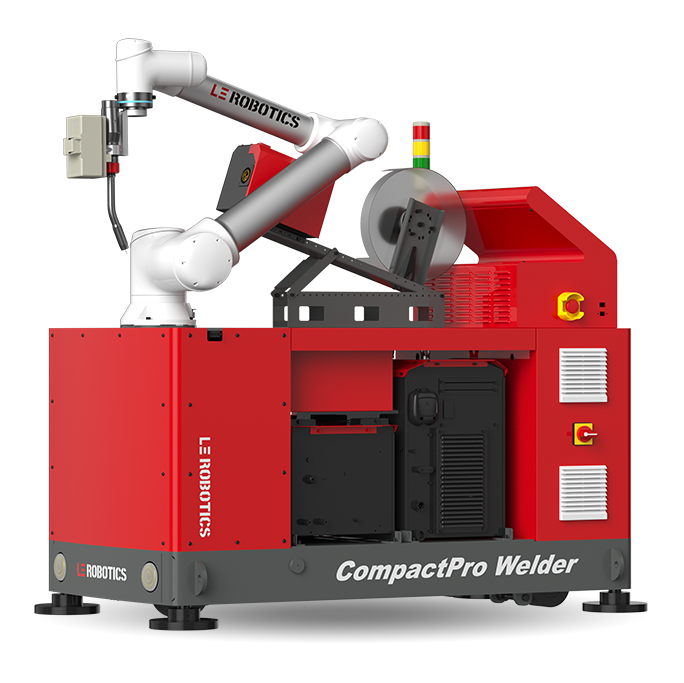

For SMEs facing welding challenges (limited budgets, small-batch/multi-type welding of general equipment/small components), it enables "low-cost intelligent welding" via collaborative robots: Lightweight, quick-connect power supply, fast retooling for multi-scenario efficiency/cost savings.

Loyalty AI Welding System

Loyalty AI Welding System

Programming-free and Teaching-free

One-click Weld Seam Extraction

Automatic Calibration

Intelligent Arc Tracking

Reverse Modeling without Drawings

3D Drawing Import

Digital Twin

Automatic Recognition of Common - Shaped Workpieces

Multi - Layer and Multi - Pass Welding Process

Offline Simulation Functionality

RX Welding Process

| Category | Item | Parameter |

| Basic Parameters | Total Power | 30KVA |

| Operating Power Supply | Three-Phase Five-Wire System 3x380 V±10%/50 Hz | |

| Operating Power Supply Mode | Quick-Connect Power Supply | |

| Equipment Weight | 1000 kg(Slight Differences in Selection) | |

| Overall Dimensions (L×W×H) | 1550 mm×860mmx1500 mm | |

| Vision Performance | Vision Accuracy | ≤ 0.5 mm |

| Scanning Frame Rate | 2000 Frames/Second | |

| Standard Vision (Equipped) | RX01 | |

| Battery Performance | Battery Voltage | 48 V |

| Battery Capacity | 32ah | |

| Travel Power Supply | DC48 V | |

| Motion Performance | Robot Arm Reach | 1300 mm(Slight Differences in Selection) |

| Travel Drive | Three-Wheel Drive | |

| Control Method | Wireless Remote Control | |

| Travel Speed | 2.5km/h | |

| Application Environment | Ambient Temperature | 0°℃ to +45°℃ (Operating); -20°℃ to +60°℃ (Transport and Storage) |

| Relative Humidity | ≤90%RH(No Condensation) |

Contact