Hu Haojie

Executive President (CEO) of LE Robotics

The core of industrial embodied intelligence lies in grounding technology in scenarios and forming a commercial closed loop. LE Robotics focuses on practical robot forms, uses the "hand-eye-foot-brain" technology to solve industry pain points, and expands application boundaries through industrial ecological collaboration. It always takes customer value as the anchor, enabling intelligence to truly empower industrial upgrading.

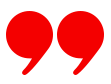

Topping the National-Level Competition

Authoritative Certification for the Leading Potential of Industrial Embodied Intelligence

▲LE Robotics Shortlisted for the Finals of the 2025 National Unicorn Enterprise Competition

Recently, the shortlist for the national finals of the 2025 National Unicorn Enterprise Competition was officially announced. LE Robotics successfully stood out with its outstanding performance in the field of industrial embodied intelligence, becoming a key focus in the industrial embodied intelligence track. Co-hosted by the Torch High Technology Industry Development Center of the Ministry of Industry and Information Technology and the Chinese Institute of Electronics, this competition is a top-tier event in China focusing on emerging industries and future industries. With the theme of "Gathering Sci-Tech Innovation Elements, Leading the Future of New-Quality Productivity", it aims to select unlisted technology-based enterprises with core technologies and high growth potential.

Since its launch in September 2025, the competition has undergone two rounds of rigorous selection: the registration stage, and the business ranking competition and comprehensive ranking competition. It covers high-quality technology enterprises from 31 provinces and 78 cities nationwide, and only a few enterprises that meet the criteria of "valuation exceeding 500 million yuan, outstanding independent R&D capabilities, and high industrial integration" have been shortlisted. It is reported that the national finals will be held offline in Ningbo National High-tech Industrial Development Zone at the end of December. Shortlisted enterprises will compete for awards through on-site roadshows, and winners will receive special support such as full-chain financial services, industrial docking, and achievement transformation. The competition's authority and industry influence are widely recognized.

LE Robotics' selection this time is attributed to its cutting-edge technologies and commercial achievements in the field of industrial embodied intelligence: relying on the "hand-eye-foot-brain" full closed-loop collaborative system, integrating core technologies such as Loyalty AI and 3D Vision Technology, it pioneered the "InstantSeam Welding" and "WeldOnMove" functions, which have been applied in high-end scenarios such as nuclear energy and nuclear power; in addition, backed by a core team composed of Tsinghua University alumni and top talents, exclusive tens of millions of yuan in Series A financing from Shenzhen Venture Capital, serving more than 50 Global Top 500 enterprises with a repurchase rate exceeding 95%, it fully meets the competition's "Four Highs" selection criteria.

Currently, LE Robotics is actively preparing for the national finals in conjunction with relevant local departments, and will fully demonstrate its technological achievements and industrialization value in the roadshow.

Hu Haojie Speaks at Industry Forum

Decoding the Core Logic of Practical Industrial Embodied Intelligence Robots

▲Hu Haojie, CEO of LE Robotics, delivered a keynote speech at the forum site

On November 19, 2025, Hu Haojie, CEO of LE Robotics, was invited to attend the "Breaking Through Changes for Symbiosis and Win-Win — 2025 China New Energy Industry High-Quality Development Forum" hosted by China Business Journal, and delivered a keynote speech. As a core parallel forum of the 8th China International PV & Energy Storage Industry Conference, this forum was grandly held in Chengdu, gathering authoritative experts, scholars and enterprise executives from fields such as photovoltaic, hydrogen energy, energy storage and intelligent manufacturing. It conducted in-depth discussions around core topics including industry transformation, technological innovation and ESG practices, pooling consensus for the high-quality development of the new energy industry.

At this event, LE Robotics successfully entered the "2025 China Business Journal New Energy Industry High-Quality Development Excellent Cases" and won the title of "2025 China Business Journal Embodied Intelligence Technological Innovation Enterprise" by virtue of its cutting-edge innovation and implementation achievements in the field of industrial embodied intelligence, fully demonstrating the industry's high recognition of its technical strength and industrial contributions.

▲LE Robotics Wins the 2025 China Business Journal Excellent Case for High-Quality Development of the New Energy Industry

When interpreting the development trend of industrial robots, Hu Haojie emphasized that the core demands of industrial scenarios are stability, precision, and reliability. Therefore, LE Robotics focuses on practical forms such as wheeled and tracked robots, deeply cultivates complex welding and cutting processes, and has formed a commercial closed loop. The core of industrial embodied intelligence is to become an "intelligent collaborative partner" that undertakes high-risk, high-intensity, and repetitive tasks, ensuring safety and solving labor shortages. He introduced that the "hand-eye-foot-brain" full closed-loop collaborative system is the technical core. Currently, the technology has been accurately adapted to high-end scenarios such as energy and rail transit, with businesses covering many parts of the world. In the future, it will continue to promote the transformation of the manufacturing industry towards intelligence and greenization.

Ecological Cooperation Upgrade

Co-building the Industrial Embodied Intelligence Industry Chain with EFORT

▲EFORT Robot CEO Wang Fukang and LE Robotics CEO Hu Haojie

Sign Strategic Cooperation Agreement

Recently, Wang Fukang, Executive President of EFORT Intelligent Robot Co., Ltd., and Wang Wanjuan, Deputy General Manager of the Marketing Center, led a core team to visit LE Robotics. Hu Haojie, CEO of LE Robotics, received them with his team and participated in the seminar. The two parties conducted in-depth exchanges on cooperation directions in the field of industrial embodied intelligence, and finally officially signed a strategic cooperation agreement, which will carry out in-depth collaboration around technology implementation, commercial scenario expansion, and industrial ecological co-construction.

As a leading enterprise in the field of intelligent manufacturing equipment, EFORT has mature advantages in the layout of the entire robot industry chain, with global channels and large-scale manufacturing capabilities, which can provide broad scenarios and production capacity support for technology implementation; LE Robotics focuses on the industrial embodied intelligent welding and cutting track, builds a core technical barrier with the "hand-eye-foot-brain" full closed-loop collaborative system, and its self-developed core software is independent and controllable, which can supplement key capabilities in segmented fields. The two parties form a high degree of complementarity in resources and technology.

At the signing ceremony, Wang Fukang stated that this cooperation will promote the upgrade of industrial robots from "tool-level application" to "capability-level empowerment", injecting new momentum into the development of the industry; Hu Haojie mentioned that this linkage is an important practice of "technological complementarity + ecological co-construction". In the future, the two parties will jointly explore the commercialization path of industrial embodied intelligence in high-end scenarios such as energy, and accelerate the transformation of technological achievements.

This strategic cooperation is not only a resource linkage between the two enterprises, but also marks the acceleration of ecological layout in the field of industrial embodied intelligence. It will provide more complete technical and service support for the intelligent transformation of the manufacturing industry and help the development of new-quality productivity.

Debut at Welding Forum

Embodied Intelligence Solution Addresses Core Industry Pain Points

▲LE Robotics Wins the 2025 Typical Application Case Award for Innovative Welding Products

From November 20 to 22, 2025, the 3rd Intelligent Welding Process Innovation Forum and the 16th Tianjin Welding Forum were successfully held in Tianjin. As a supporting organization, LE Robotics was invited to participate. Its embodied intelligent welding and cutting solution aroused widespread concern at the forum, gained high recognition from representatives of industry, academia, research and application circles, and won the 2025 Typical Application Case Award for Innovative Welding Products.

Co-hosted by 6 units including China Machinery Industry Information Institute and Tianjin Welding Industry Association, this forum closely follows the development requirements of "new-quality productivity", focuses on the innovation of intelligent welding processes, and builds a collaborative exchange platform for the industry's technological upgrading. As the "industrial lifeline" of the manufacturing industry, welding is currently facing pain points such as high dependence on manual labor, high operational risks in high-risk environments, and insufficient quality stability. Especially in high-end fields such as marine engineering, nuclear power, and hydrogen energy transportation, the requirements for welding intelligence and precision are becoming increasingly stringent. The industry is in urgent need of innovative solutions to break through development bottlenecks.

The embodied intelligent welding and cutting solution displayed by LE Robotics accurately responds to the industry's transformation needs. With the "hand-eye-foot-brain" full closed-loop collaborative system as the core, the solution realizes the autonomy and intelligence of welding operations. Through the in-depth integration of AI technology, the robot has the ability of autonomous perception, decision-making and execution in complex scenarios, which can efficiently undertake high-risk, high-intensity and repetitive tasks, and solve the industry's labor shortage problem.

At present, this solution has been applied in high-end scenarios such as energy, rail transit, and large-scale infrastructure, providing a feasible practical path for the intelligent transformation of the welding industry.

——END——

Contact